Blog

NYC’s Top Pizza for Just $1 Per Slice TONIGHT!

Great slices for $1 in NYC? Did I accidentally step into a time machine? We’re back after a 4.5 year absence! Slice Out Hunger’s Dollar Pizza

New Scholarship Supports Women in Pizza

March is Women’s History Month and that means it’s the perfect time to honor and support women in the pizza world! Pizza has long been

Another San Marzano Tomato Lawsuit

A fresh San Marzano tomato lawsuit questions the veracity of one of the most iconic can labels on the planet. We’ve all seen it in

Is NYC the Nation’s Most Expensive Pizza City? NO!

Does NYC have the nation’s most expensive pizza? The NY Post recently published an article about how NYC’s pizza was more expensive than any other

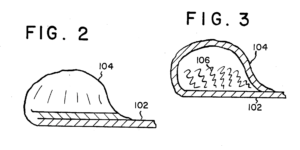

The True Origin of Stuffed Crust Pizza?

I just heard the most incredible story on the Brooklyn Magazine podcast thanks to a tip from SPT guide Amy. Apparently there’s a guy in

How To Order Pizza for Super Bowl Sunday

Super Bowl LVIII is coming up this Sunday and if you’re not ready it’s going to be a total dining disaster. Known to be one

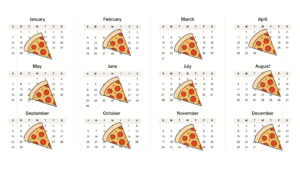

2024 Pizza Calendar

To celebrate National Pizza Week, we’re simplifying your life with this 2024 pizza calendar. Plan accordingly and have a fantastic week! January14-20 National Pizza Week27 Vegan

My New Favorite Pizza Dough Recipe

Even though I live in New York City, a place with more pizza than any one person can eat, I still enjoy making it at

Joshua Weissman Tried NYC’s Best Pizza

Joshua Weissman is a chef, bestselling author, YouTube creator, and now he’s a pizza nerd. I spent two days with him shooting a video about

Peter Reinhart’s Podcast from Pizza & Pasta Northeast

Peter Reinhart is an author and educator dedicated to teaching the beauty and joy of bread. His TED Talk is legendary and his books cover

My Pizza Box Collection Has a New Home

My pizza box collection has come a long way since I started it back in 2009. I recently moved it into a storage facility, making

Military-Grade Pizza MRE

I’m a lover of The Sporkful podcast so you can imagine my excitement when my audio app served up a fresh new episode called “How

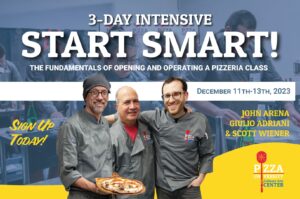

3-Day Pizza Class at Pizza University

I’m excited to announce that I’ll be teaching a 3-Day pizza class December 11-13 at Pizza University alongside my mentors John Arena (Metro Pizza) and

Pizza Boxes on Freakonomics!

Freakonomics Radio is an outstanding podcast network with shows that examine the intersection of economics and culture. They have a great show called The Economics

New Pizza Podcast Alert

Just over a year ago I posted a listeners’ guide to pizza podcasts. There are at least a half dozen and they all approach pizza